BuildingIQ Develops Proactive Algorithms for HVAC Energy Optimization in Large-Scale Buildings

Challenge

Solution

Results

- Gigabytes of data analyzed and visualized

- Algorithm development speed increased tenfold

- Best algorithmic approaches quickly identified

“MATLAB has helped accelerate our R&D and deployment with its robust numerical algorithms, extensive visualization and analytics tools, reliable optimization routines, support for object-oriented programming, and ability to run in the cloud with our production Java applications.”

Office buildings, hospitals, and other large-scale commercial buildings account for about 30% of the energy consumed worldwide. The heating, ventilation, and air-conditioning (HVAC) systems in these buildings are often inefficient because they do not take into account changing weather patterns, variable energy costs, or the building’s thermal properties.

BuildingIQ has developed Predictive Energy Optimization™ (PEO), a cloud-based software platform that reduces HVAC energy consumption by 10–25% during normal operation. PEO was developed in cooperation with the Commonwealth Scientific and Industrial Research Organisation (CSIRO), Australia’s national science agency. Its advanced algorithms and machine learning methods, implemented in MATLAB®, continuously optimize HVAC performance based on near-term weather forecasts and energy cost signals.

“CSIRO used MATLAB to develop the initial technology. We continue to use MATLAB because it is the best tool available for prototyping algorithms and performing advanced mathematical calculations,” says Borislav Savkovic, lead data scientist at BuildingIQ. “MATLAB enabled us to transition our prototype algorithms directly into production-level algorithms that deal reliably with real-world noise and uncertainty.”

Challenge

BuildingIQ needed to develop algorithms that could continuously process gigabytes of information from a variety of sources, including power meters, thermometers, and HVAC pressure sensors, as well as weather and energy cost data. A single building often produces billions of data points, and the scientists and engineers needed tools for efficiently filtering, processing, and visualizing this data.

To run their optimization algorithms, the scientists and engineers had to create an accurate mathematical model of a building’s thermal and power dynamics. The algorithms would use this calculated model to run constrained optimizations that maintained occupant comfort while minimizing energy costs.

BuildingIQ needed a way to rapidly develop mathematical models, test optimization and machine learning approaches, prototype algorithms, and deploy them into its production IT environment.

Solution

BuildingIQ used MATLAB to speed up the development and deployment of its predictive energy optimization algorithms.

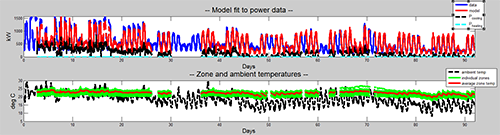

The optimization workflow begins in MATLAB, where BuildingIQ engineers import and visualize 3 to 12 months of temperature, pressure, and power data comprising billions of data points. They use Statistics and Machine Learning Toolbox™ to detect spikes and gaps, and remove noise produced by sensor failures and other sources using filtering functions in Signal Processing Toolbox™. BuildingIQ engineers fitted a mathematical model developed in MATLAB to the denoised data using least squares fitting functions from Optimization Toolbox™. This measurement and verification (M&V) model correlates ambient temperature and humidity with power consumed by the HVAC system.

As part of the modeling process, they use SVM regression, Gaussian mixture models, and k-means clustering machine learning algorithms from Statistics and Machine Learning Toolbox to segment the data and determine the relative contributions of gas, electric, steam, and solar power to heating and cooling processes.

The team builds a PEO model in MATLAB that captures the effect of the HVAC system and ambient conditions on internal temperatures in each zone, as well as on the total power consumption for the building. Using Control System Toolbox™ they analyze HVAC control system poles and zeros to estimate overall power consumption and determine how quickly each zone is likely to converge to its set point.

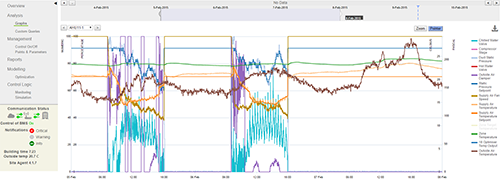

BuildingIQ engineers use Optimization Toolbox and the PEO model to run multi-objective optimizations with hundreds of parameters, as well as nonlinear cost functions and constraints to continuously optimize energy efficiency in real time. These optimizations take into account projected weather and energy prices over the next 12 hours, and identify optimal HVAC set points. In operation, Java® software in the cloud invokes the MATLAB optimization algorithms periodically throughout the day.

Each day, BuildingIQ calculates baseline energy cost from the M&V model representing what the client would have paid for HVAC energy without the BuildingIQ PEO platform. Savings range from 10% to 25%.

Results

Gigabytes of data analyzed and visualized. “MATLAB makes it easy to process and visualize the big data sets we work with,” says Savkovic. “We create scatter plots, 2D and 3D graphs, and other charts that display in a meaningful way how our system is performing.”

Algorithm development speed increased tenfold. “Developing algorithms in MATLAB is 10 times faster and more robust than developing in Java,” says Savkovic. “We need to filter our data, look at poles and zeroes, run nonlinear optimizations, and perform numerous other tasks. In MATLAB, those capabilities are all integrated, robust, and commercially validated.”

Best algorithmic approaches quickly identified. “With MATLAB we can rapidly test new approaches to find the one that works best for our data,” says Savkovic. “For example, we tested several optimization approaches before selecting sequential quadratic programming, and we tried several clustering machine learning algorithms. It’s a huge advantage to explore different methods so quickly.”